Featured News, Market News

WHAT IS IQF BANANA? THE EXPORT POTENIAL OF VIETNAM’S IQF BANANA

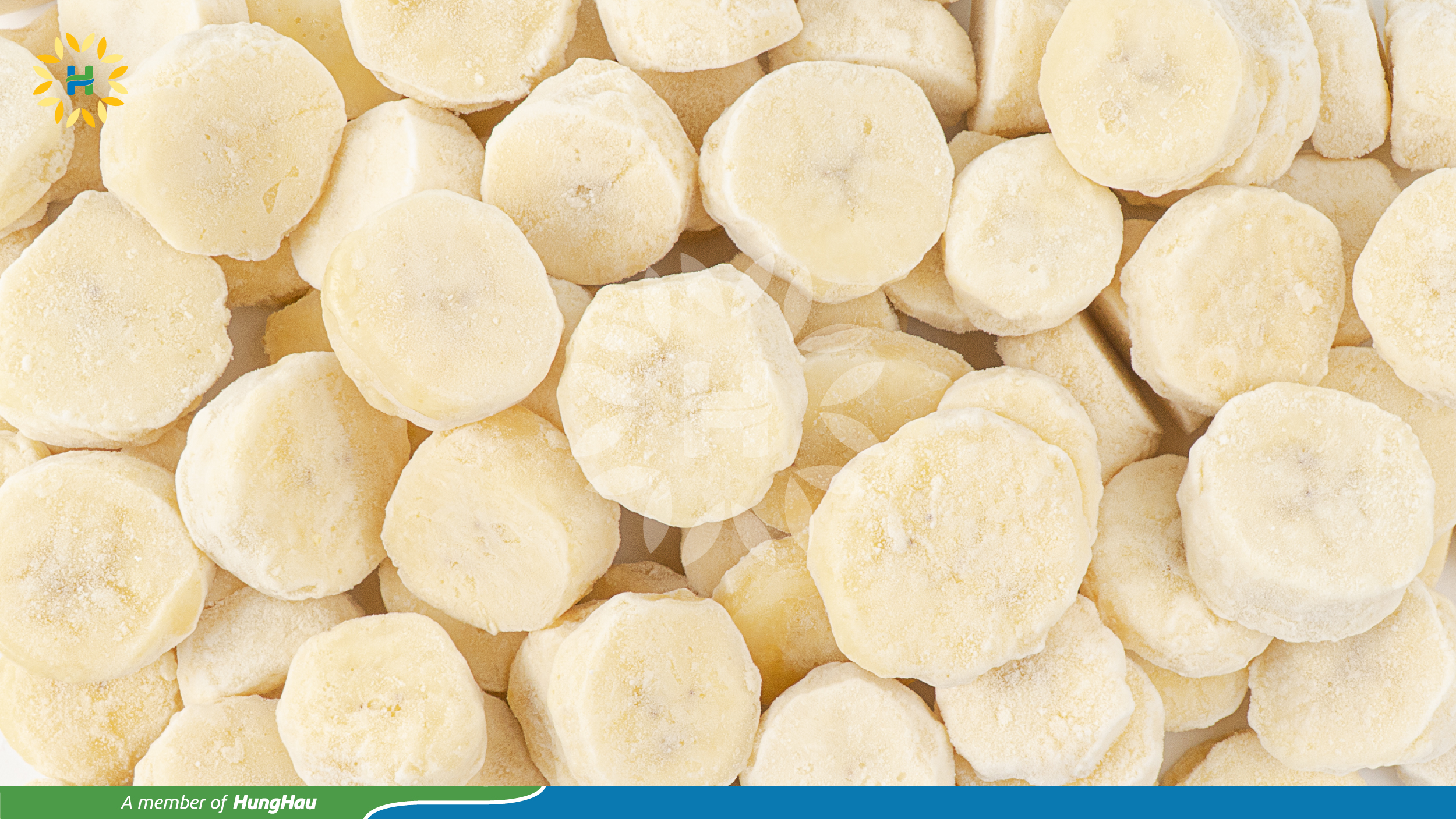

IQF Bananas are increasingly emerging as a standout product in Vietnam’s frozen fruit industry.

Thanks to advanced processing technology, IQF banana not only retain their natural flavor, color, and nutritional value but also offer extended shelf life — meeting the strict standards of international export markets. So, what exactly are IQF banana, how are they produced, and why are they considered a “catalyst” for Vietnam’s IQF fruit industry? Let’s explore the details in the article below.

WHAT IS IQF BANANA?

IQF (Individual Quick Frozen) banana are bananas that are rapidly frozen either whole or in individual slices using IQF technology — a modern ultra-fast freezing method that preserves the fruit in its most natural state.

Advantages of IQF Bananas Compared to Conventional Frozen Bananas

-

Non-sticky texture: Thanks to individual quick freezing, the bananas do not clump together, making it easy to use just the right amount.

-

Preserved flavor, color, and texture: IQF bananas remain firm and vibrant, unlike traditionally frozen bananas which can become mushy or discolored.

-

Easy to store and distribute: Ideal for streamlined logistics and meets international quality standards.

Compared to Fresh Bananas:

-

Not season-dependent: Can be supplied year-round.

-

Extended shelf life: Lasts 12–24 months when stored under proper conditions.

-

Export-friendly: Maintains quality throughout long-distance transportation.

-

Optimized logistics: More cost-effective in transport and storage than fresh produce.

IQF Banana Production Process

Producing IQF bananas requires advanced technology and strict quality control to ensure product consistency and safety:

-

Raw material selection: Only evenly ripened, undamaged bananas that meet export standards are selected.

-

Washing and pre-processing: Peeling and slicing according to requirements (whole, round slices, lengthwise slices, diced, halved, chunked, etc.).

-

Blanching (optional): Helps eliminate bacteria and preserve natural color.

-

IQF quick freezing: Instantly frozen at -35°C to -40°C within minutes.

-

Packaging and storage: Air-tight packaging, stored at -18°C or below.

IQF technology helps retain maximum nutritional value — including vitamin B6, vitamin C, potassium, magnesium, and fiber — making it an ideal product for premium consumer markets.

Applications Of IQF Bananas In The Food Industry

IQF bananas are not only a strong export product but also enjoy high demand across multiple sectors:

Ingredient for the F&B Industry

Used in smoothies, juices, bubble tea, and other blended beverages.

Ideal for cafés, restaurants, and modern beverage chains due to its convenience and consistent quality.

Industrial Food Production

Serves as a key ingredient in ice cream, bakery products, breakfast cereals, and snacks.

Widely favored by food manufacturers for its ease of use and uniformity.

Export Potential Of Vietnam’s Frozen Banana

Large-scale production and varietal diversity

Vietnam has established itself as one of Southeast Asia’s leading banana producers.

According to the Food and Agriculture Organization (FAO, 2023), Vietnam ranked fourth in banana production in the region, after Indonesia, the Philippines, and Thailand.

In 2023, the country’s total banana output reached approximately 2.5 million tons, marking a 6.5% increase compared to the previous year (Vietnam General Statistics Office, 2023).

Vietnam is home to a wide range of high-quality banana varieties. Popular types include:

-

Finger banana and Pisang Awak banana (widely consumed domestically)

-

Cavendish Banana form (dominates export markets)

-

Laba bananas from Da Lat (a high-value specialty variety)

-

Chuối Cau, commonly grown in southern provinces

Major banana-growing regions include Dong Nai, Long An, An Giang, Gia Lai, Binh Phuoc, Lam Dong, and Tien Giang, with a total cultivation area of approximately 120,000 hectares (Ministry of Agriculture and Rural Development, 2023).

Commercial Potential of Frozen Banana

Development of the Frozen Banana Processing Industry

Thanks to an abundant supply of raw materials, Vietnam’s frozen banana processing industry is experiencing strong growth. Major enterprises such as Hung Hau Foods Joint stock Company (HungHau Foods) and Hoàng Anh Gia Lai have invested in the application of IQF (Individual Quick Freezing) technology to enhance product quality. In 2023, export turnover of frozen bananas reached USD 250 million, marking a 20% increase compared to the previous year (Vinafruit, 2023). Key products include frozen banana slices (accounting for 60% of total exports), whole frozen bananas, and banana powder used in the food processing industry.

According to ITC reports, IQF fruit products, including IQF banana, are among the fastest-growing categories in Vietnam’s agricultural exports.

Main Export Markets

Vietnam’s major export markets for frozen bananas include:

-

China (accounting for 45% of total export value)

-

Japan (18%)

-

South Korea (12%)

-

European Union (10%)

The diversification of export markets helps minimize risks and stabilize the output for Vietnamese banana products.

Export Development Strategy

The Vietnamese government has set a target of placing the country among the top 10 banana-exporting nations globally by 2030. To achieve this goal, the banana export sector needs to:

-

Expand into new markets, especially the Middle East and the United States;

-

Develop a sustainable value chain from cultivation to processing;

-

Apply advanced technologies to increase productivity and product quality.

With available potential and a well-planned development strategy, Vietnam’s banana export industry is on a strong growth trajectory, making a significant contribution to increasing the value of national agricultural exports.

Trusted Suppliers of Frozen Bananas and IQF Bananas in Vietnam

Currently, many companies in Vietnam are involved in the production and supply of frozen bananas. However, to ensure international quality standards, it is important to choose suppliers with certified production processes, such as HACCP, ISO, and FDA certifications.

One standout name in the industry is Hung Hau Foods, known for its strong production capabilities and extensive experience:

Hung Hau Foods – A Leading IQF Fruit Processor in Vietnam

With over 10 years of experience, HFN Factory (Nha Man Co., Ltd.), a subsidiary of Hung Hau Foods Joint stock Company (HungHau Foods), operates a modern IQF processing line with high capacity, meeting international standards and certifications.

Hùng Hậu Foods has received the Vietnam National Brand Award five times—proof of the company’s quality and sustainability in the processed food industry.

Order high-quality IQF bananas from: IQF Banana – Công ty Cổ phần Thực phẩm Hùng Hậu (Hùng Hậu Foods)

IQF frozen bananas are a strategic direction for enhancing the value of Vietnamese agricultural products. These products retain their nutritional quality, are easy to store, are not dependent on seasonality, and have strong export potential—even to demanding markets.

Thanks to modern production processes, pioneering companies like Hung Hau Foods Joint stock Company (HungHau Foods) are playing a key role in bringing Vietnamese frozen bananas to the international market, helping to solidify the position of Vietnam’s IQF fruit on the global export map.

Contact Us